Minnesota Wire

Future Focused,

Changing the world

One Project at a Time

Innovative designs and engineering techniques, Minnesota Wire custom designs, develops, and manufactures wire, cable, and interconnect assemblies. Check out all the Minnesota Wire Capabilities to solve your problem.

Industries Served

Medical Wire

Medical Wire,

Cable, and Cable Assemblies

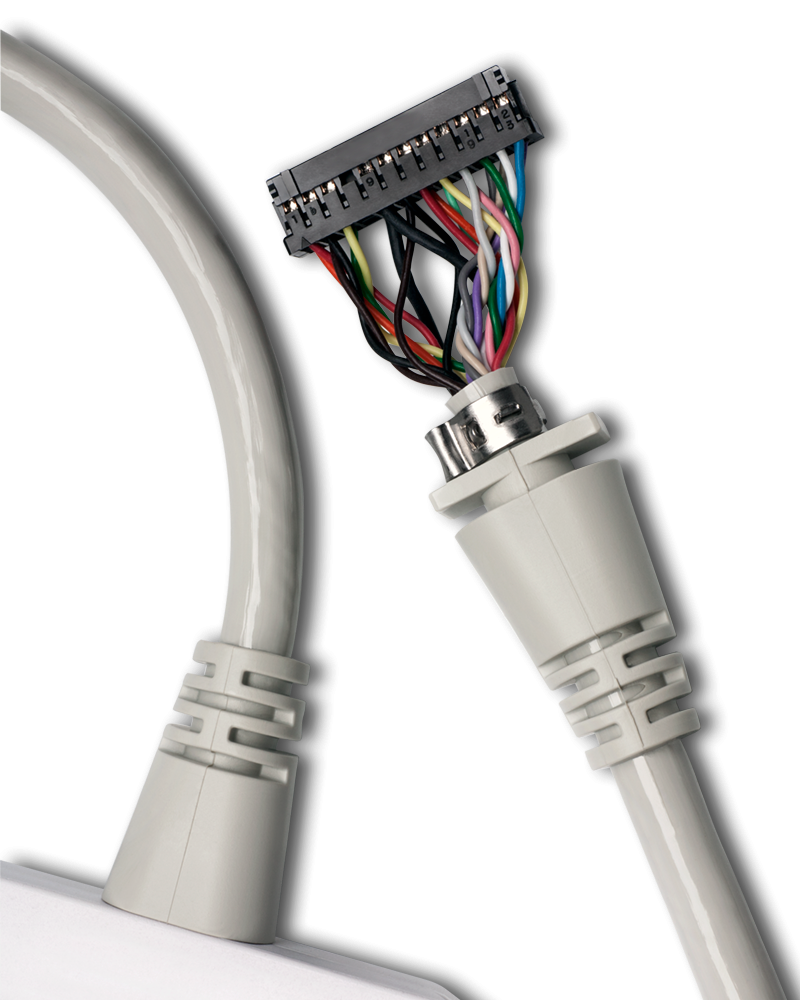

Minnesota Wire engineers and manufactures custom medical solutions for complex cable assemblies. We are a full-service development and manufacturing house for wire, cable, harness, and interconnect assemblies.

Minnesota Wire is Vertically Integrated

Vertical integration is a rarity in the wire and cable business. We expedite your project from concept to production—all in our facilities. Our in-house capabilities include concept design, prototyping, design verification, production, testing, and product validation.

Custom Manufacturing

Wire Manufacturing Company

Trusted Advisors for Over 50 Years!

Minnesota Wire utilizes a variety of advanced manufacturing methods to produce custom cable assemblies, medical cables, and medical wire.

Space Technology Wire

Space Technology Wire,

High-Temperature Cable, Lightweight Cable, Cable Assemblies, and Custom Connectors

Minnesota Wire leads the industry in development and design of lightweight wire, high-temperature cable, cable assemblies, and custom connectors that not only meet but exceed expectations in extreme environments.

Our state-of-the-art testing facilities and full Research and Development department support every aspect from prototyping to testing to ensure every detail of your project meets your specifications.

Whether you need wire and cable, or wire and cable assemblies with custom connectors in a unique configuration, we would welcome the opportunity to assist you with your next custom project. Witness first-hand why our customers refer to Minnesota Wire as their trusted advisors in the industry.

Capabilities:

Assembly to Wrap and Sintering . . . and Everything In Between

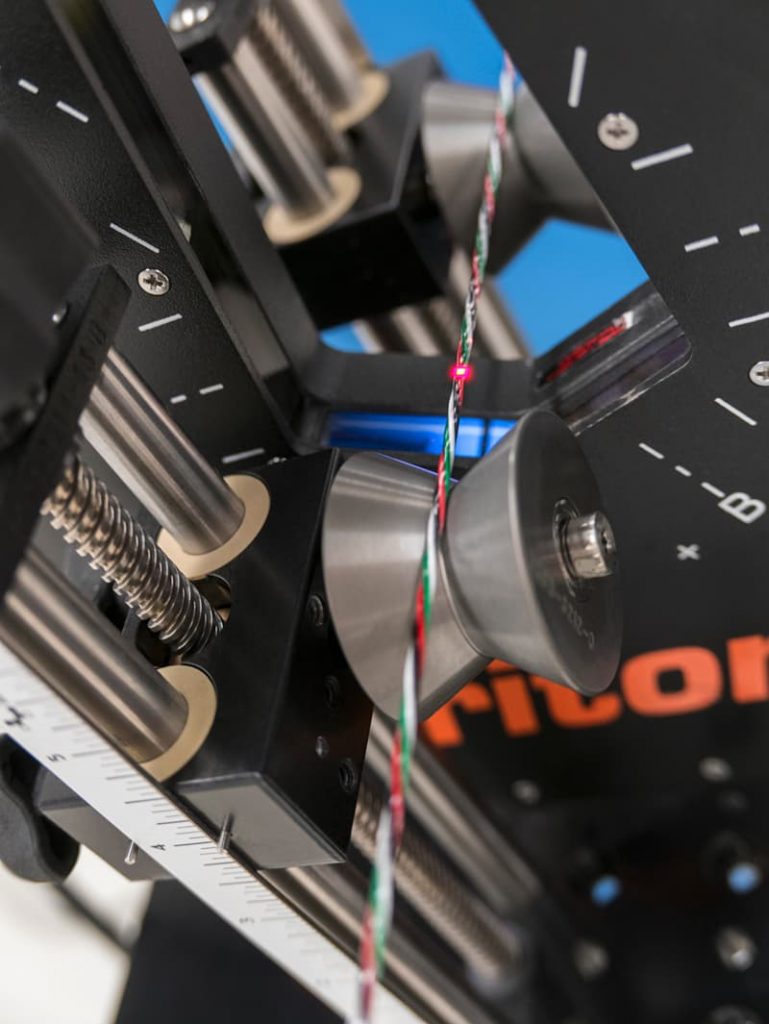

Minnesota Wire earns trust and respect from our customers by utilizing our fully integrated plethora of capabilities to ensure every product meets and exceeds their expectations. We proudly offer a full in-house range of capabilities and solutions including an design and engineering, new and unique raw materials, prototyping/3D modeling, shielding, automation, extrusion, assembly and testing / validation.

Minnesota Wire Does It All For YOU!

Defense Wire

Custom Defense Wire

and Cable Assemblies

Minnesota Wire’s extensive experience in manufacturing MIL-SPEC cables and cable assemblies led to our development of ruggedized, overmolded cables widely used in our National Defense.

Our in-house overmolding capabilities are state-of-the-art. Overmolding allows for a strong bond between two different materials without the use of adhesives. We can overmold connectors, strain reliefs, grommets, yokes, and other applications.

Overmolding increases the durability and longevity of a product. Our on-site testing facilities can document the improvement in performance that our overmolding services provide.

Manufacturing Exactly What You Need

Our seasoned engineering staff can assist with all your wire, cable, and assembly needs. From design to delivery, Minnesota Wire provides impeccable solutions for complex wire, assembly, and cable projects.

Industrial Wire

Custom Industrial Wire, Cable, and Complete Interconnect Solutions

We are a custom electrical wire and cable interconnect provider for the commercial and industrial wire and cable market. We manufacture audio, robotics, communications, high-temperature applications, sensor probe cable, and wire assemblies.

Minnesota Wire offers Design Services, Project Management, Engineering Services, Prototyping, Lean Six Sigma and 5S Methodology, Research & Development, Project Conception, and Four In-house Testing Laboratories.

iSTRETCH®

iSTRETCH is an electrical conductor that stretches and returns to its original size. It will stretch 40% while maintaining the electrical properties.

The working length of 40% allows for generous movement with a nominal pull force. Our technology ensures when an iSTRETCH cable reaches the end of its working length, it stops expanding.

With a variety of cable configurations available, iSTRETCH cables solve the most challenging aspects of any project. iSTRETCH cables are Minnesota Wire designed iSTRETCH cables for extended flex life, high vibration and extreme environmental conditions. They have increased flexibility and durability over standard cables. iSTRETCH is RoHS compliant, and washable.

A Heritage of Excellence

In 1968, Minnesota Wire’s story began at the kitchen table of founder, Fred Wagner. The Wagner family continues the legacy of our, is a privately owned custom wire and cable manufacturer. The Company transformed from a bulk cable manufacturer to an industry leader in custom wire and cable manufacturing. Minnesota Wire excels in cable assemblies, R&D, testing, and design engineering.

Careers

Let’s change the world together. It will be fulfilling to come to work every day and create industry-leading products.

News, Articles & Tools

Minnesota Wire Registers Its Eighth Patent

The experts in space technology, military, and medical cables have confirmed the latest development for its carbon nanotube wire.