Capabilities

Assembly to Wrap and Sintering . . . and Everything In Between

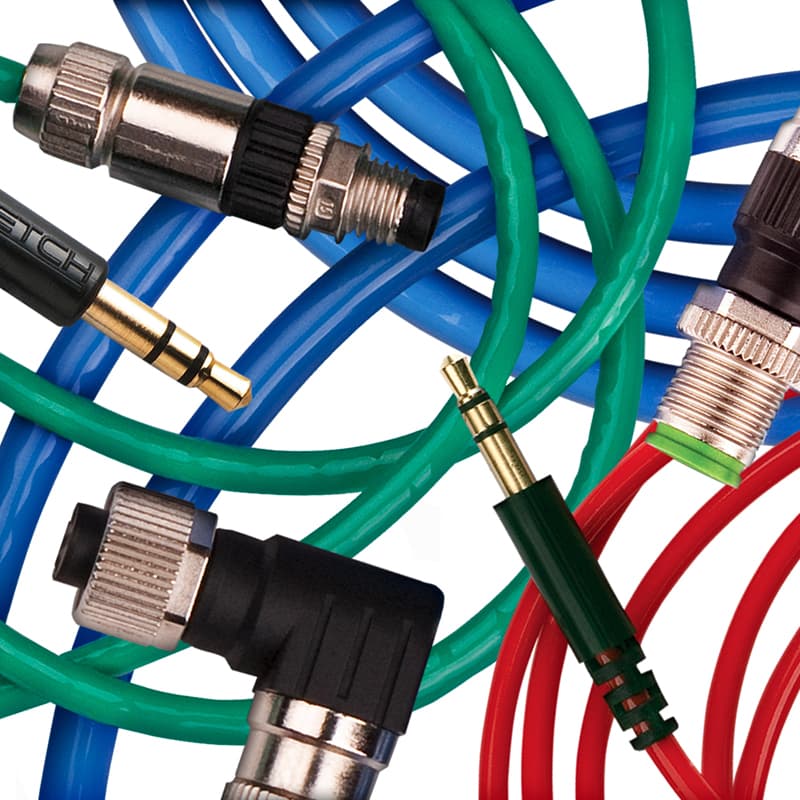

Assembly

We cut the wire to the desired length on a wire-cutting machine. The wires are then stripped to expose the metal. Next, the wires are fitted with terminals or connector housings. Finally, the cables are assembled and clamped together according to the design specifications.

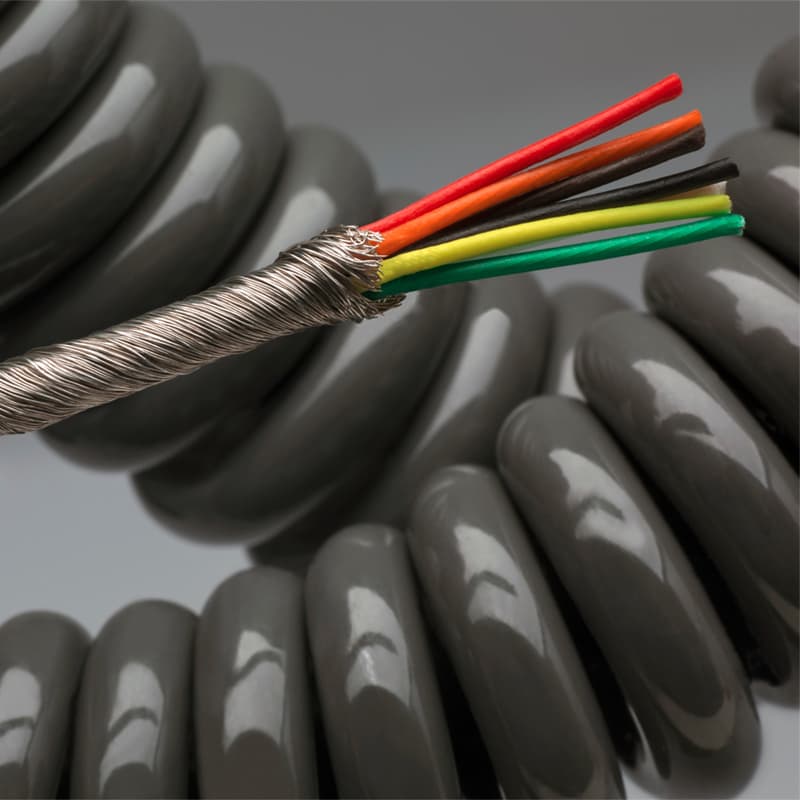

Cable Coiling

We offer a wide variety of coiling constructions. Our coil cords are available in axial, tangent, and performed tails. Coil cords can be designed with controlled retraction force.

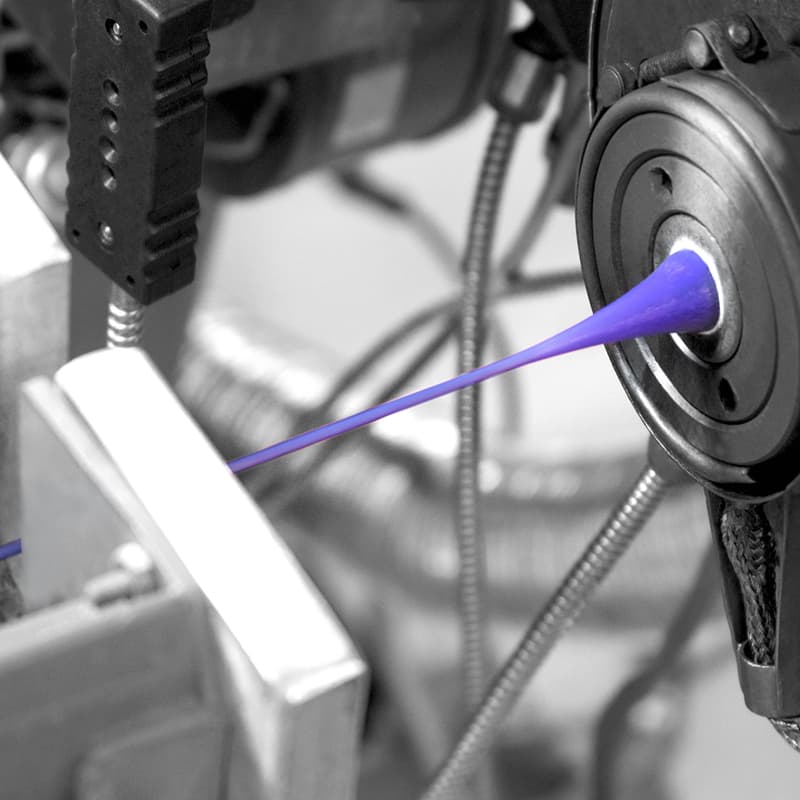

Extrusion

Our extrusion process creates a protective and aesthetic coating on a bare wire. The bare wire is pulled through the center of a die to create a colored, insulated jacket. This process is high volume and creates a continuous and consistent profile. Our fluoropolymer extrusion line allows for the insulation of wires and cables with aerospace qualified polymers. Please select Materials for a list of materials we extrude.

Fine Braiding

We braid round and flat shields. Our shields stop electromagnetic interference, block external noise, resist abrasion, increase overall pull and cut-through strength, and protect from fire.

Intelligent Cables

The integrated circuit and software on the circuit detect the charging requirements of the device into which the intelligent cable is plugged.

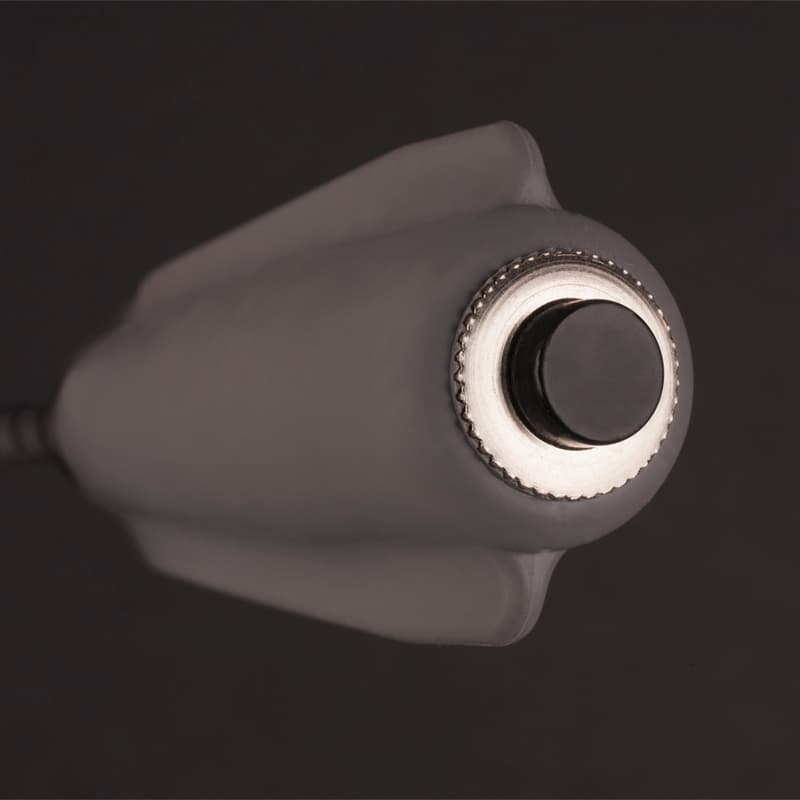

Molding

Insert molding enhances a cable assembly’s functionality, durability, and aesthetics. These enhancements are achieved by encasing areas of the cable assembly with plastics such as PVC, PP, TPEE, and TPR.

Overmolding allows for a strong bond between two different materials without the use of adhesives. We can overmold connectors, strain reliefs, grommets, yokes, and other applications.

Prototyping

We create functional prototypes. A working prototype gives you certainty in the design of your project. We can help you develop your custom design. We have years of experience designing for a myriad of applications. We can source the necessary materials to develop and manufacture your product. We can do it all in our facilities.

Robotic Termination

We can robotically terminate wires with the use of our MTX machine. This automated process offers significant cost savings for high-volume products that do not require custom terminations and overmolding.

Let Our Expertise Guide You!

Minnesota Wire utilizes a variety of advanced manufacturing methods and raw materials to enhance your project.

Shielding & Cabling

We have complete in-house capabilities to shield multiple insulated conductors. This allows us to enclose a common conductive layer. We use rigorous, proprietary tests to ensure quality in all of our cables.

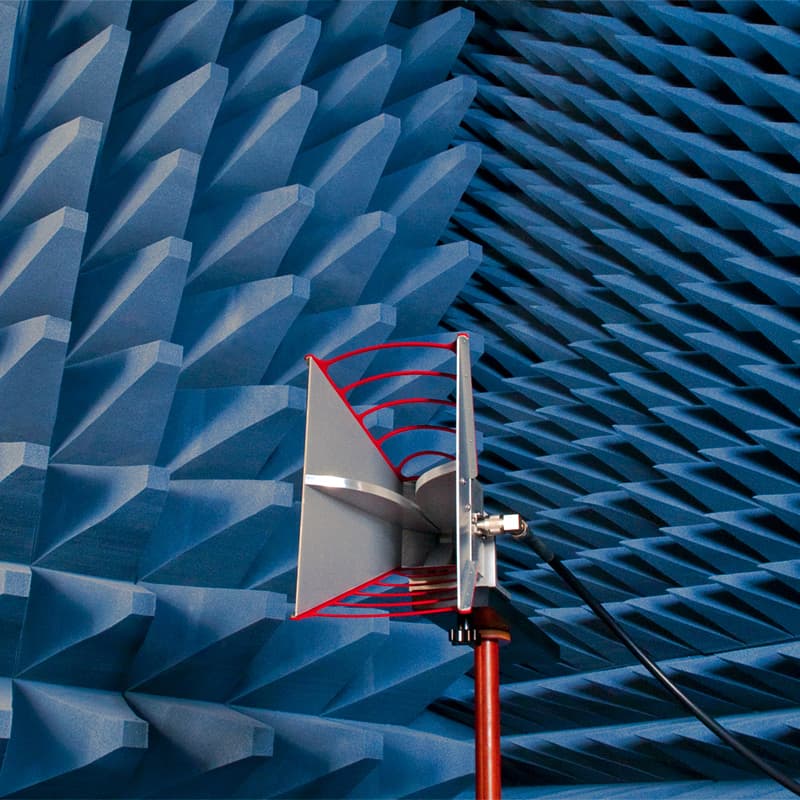

Electrical Testing Lab

Our electrical lab features an EMI chamber. We can provide full pre-compliance electromagnetic compatibility and shielding effectiveness testing for prototypes, finished electrical sub-components, and full assemblies.

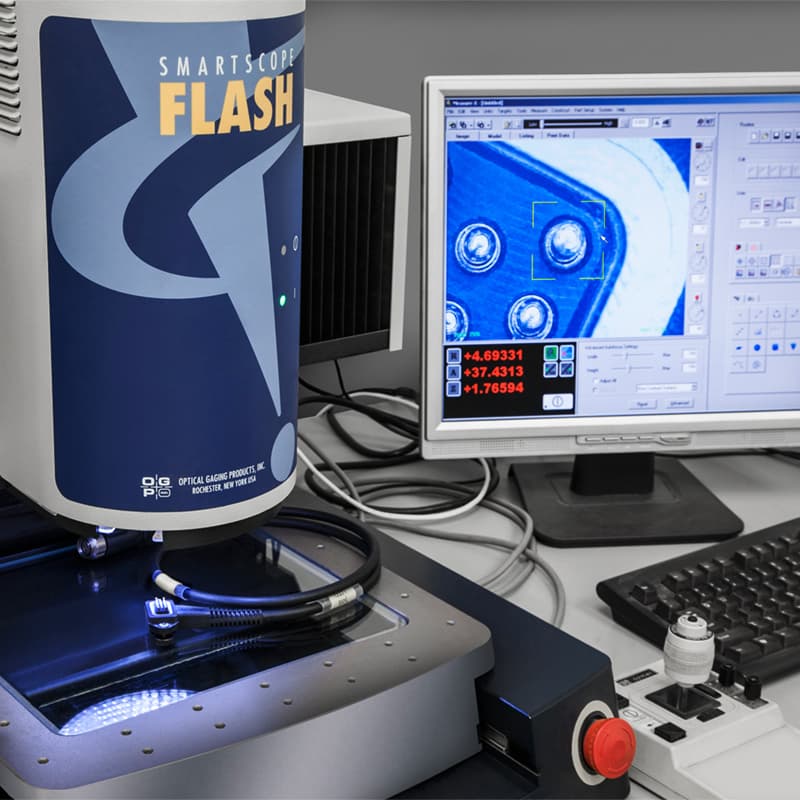

Mechanical Testing Lab

Our mechanical lab offers complete test and measurement.

Nanotechnology Lab

Our nanotechnology lab enables us to experiment with carbon nanotubes on non-metallic conductors and shields. Our testing has already paid dividends. We have identified and are now developing new processes for the use of carbon nanotubes in wire and cable manufacturing.

Signal Integrity Testing Lab

Our signal integrity lab allows us to test electrical integrity and shielding effectiveness.

Testing Capabilities Include

Our testing capabilities include flex life, stretch, torque, low noise, submersion, high-speed thermal mass flow leak, tensile and compression (pull test), OGP SmartScope 250 (Non-contact optical comparator), impulse/abrupt, MIL-C-17G (cable test), and AAMI/ANSI EC53-1995.

Tooling

We have an accomplished tooling design and fabrication department. We can create nearly any mold for the wire and cable industry. Our engineered designs are created in a software program for maximum throughput. Each mold is designed for manufacturing ease. The mold is then made on our CNC machine, guaranteeing precision measurement.

Value-Added Services

We can cut, strip, crimp, and terminate one or both ends of a wire. This automated process guarantees accuracy and saves time and labor.

Wrap and Sintering

We have insulation, dielectric, and shielding capabilities. Processing materials include PTFE, polyester, polyimide (Kapton & Oasis), metal foils, metalized polymer tapes, and unique conductive tapes.