Custom Medical Wire, Cable, Connectors, and Cable Assemblies

Since 1968, Minnesota Wire has been an industry leader in design, manufacturing and testing of custom wire, cable, connectors and cable assemblies for the medical industry.

Minnesota Wire proudly services customers from start-ups to industry leaders. We welcome the opportunity to assist you with the design and production of your custom medical products. We produce everything from prototypes for testing to mass production of your final custom cable assemblies and wire.

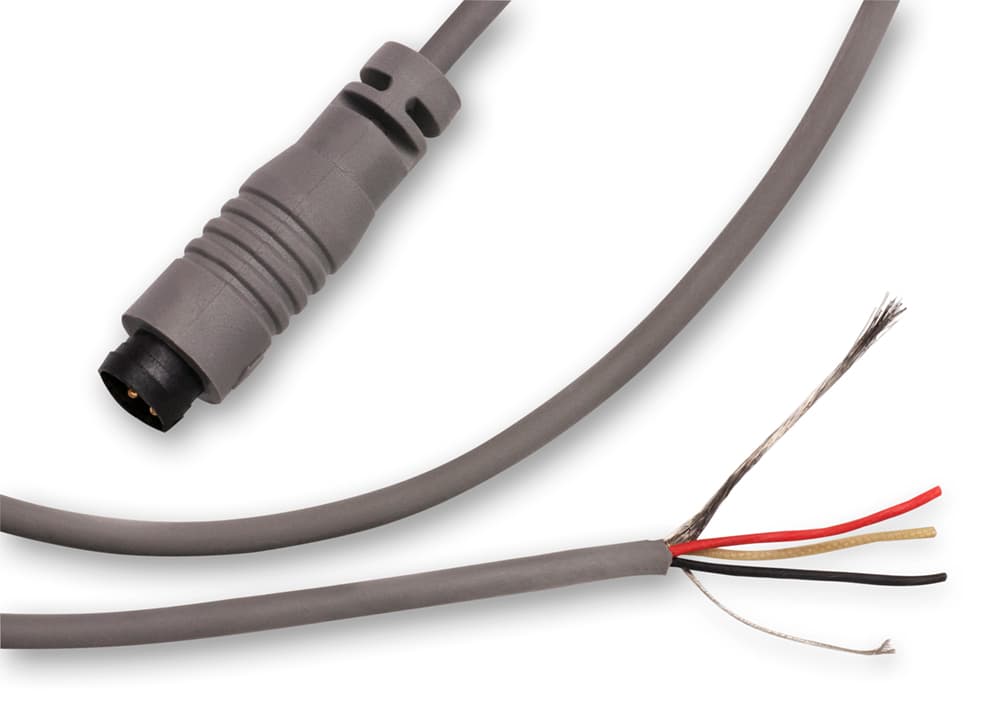

Teflon wrap underneath Braid helps with stripping and prevents abrasion of inner wires from braid during cable flexing.

Braided tinned copper shield, reduces cable flexibility but increases resistance to mechanical failure, and provides signal shielding for the data wires within the cable.

TPE Jacket selected for good biocompatibility properties and durability to survive repeated use.

Sub bundles individually foil shielded for signal integrity.

Wires split into sub bundles for signal isolation purposes. Wrapped together in teflon to keep sub bundles together and protect individual shields from abrading on outer shield, and keeps outer and inner shields independent.

Crimp style contacts applied for insertion into molex or similar housing.

Some splices added to create jumpers for common grounds. This reduces the number of wires in the cable and helps reduce cable size.

Pins crimped on prior to insertion into custom connector housing.

More jumpers.

Pins inserted into custom connector

Back end filled with potting material to immersion proof and help prevent damage during overmold process.

Materials selected to ensure adherence of overmold to connector.

Material selected to ensure bonding of overmold and cable jacket.

These selections along with a water proof connector allow the cable assembly to survive the cleaning process without risk of trapping cleaning fluid or shorted contacts.

Our Capabilities

Over molded Connectors

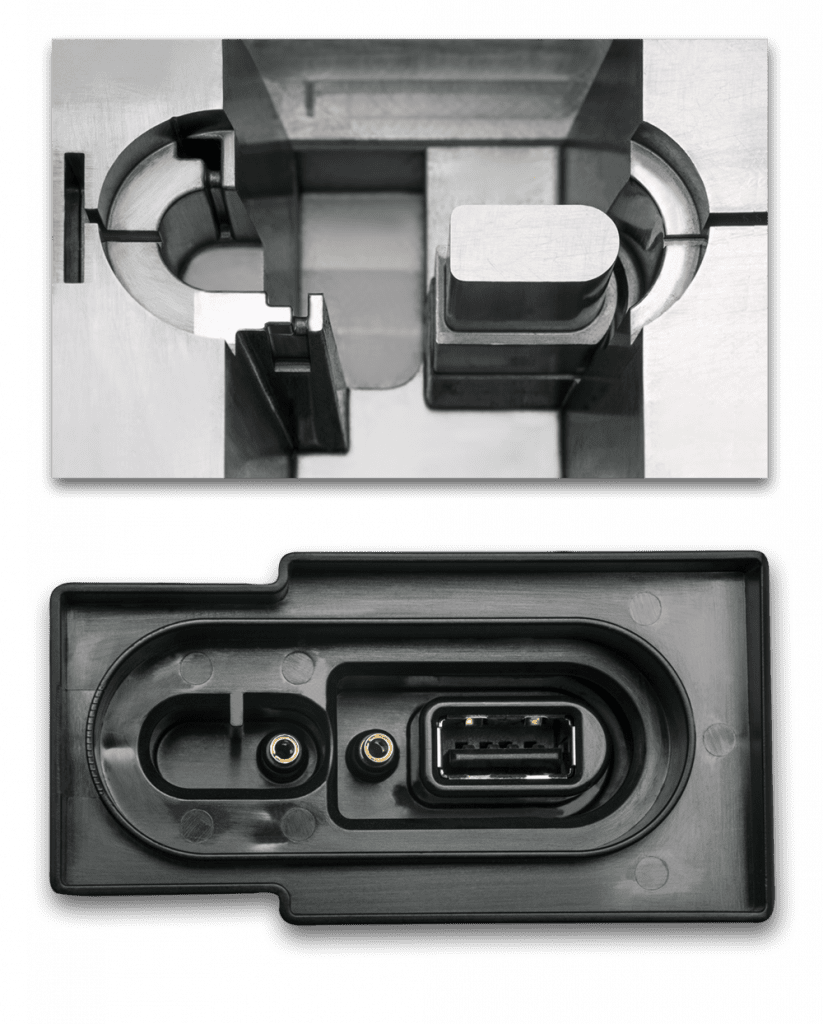

Our in-house tooling department matches or custom builds nearly any mold. Whether starting from scratch or reverse-engineering any product and fabricate required for mold tooling for over molding, our engineers and tooling department has you covered.

When a standard off-the-shelf connector will not meet performance expectations and requirements, Minnesota Wire provides a unique solution including custom over molded connectors.

Complete Electrical Solutions

We offer complete electrical solutions, from jacketing extrusion to wire termination to custom connectors.

Our engineering department and R&D division enable us to develop new and innovative solutions for challenging medical wire and cable applications. Our test and measurement laboratories help ensure every medical wire, cable, cable assembly, and connector meet or exceed your expectations.

In-House Tooling and Rapid Prototyping

We have in-house tooling and rapid prototyping capabilities to get new projects off the ground quickly and efficiently. Our high volume and lean production capabilities allow us to produce custom medical wire and custom cable assemblies in the quantities you require—in the time frame you need.

Custom Medical Products Manufacturing

Minnesota Wire utilizes a variety of advanced manufacturing methods to produce our products. We will work with you to develop the perfect custom solution for your unique engineering needs.

Our Expertise Includes

Electrical Signal Integrity (SI) and EMI Shielding

Low-Noise Medical Wire and Cable

Innovative Connections for Wearable Electronics and Patient Monitoring Systems

Carbon Fiber Wire for Imaging

Developed for the disposable AED electrode market, these specialized wires are barely visible on x-ray and other imaging equipment, which eliminates the need to remove electrode wires from the patient before imaging.

ECG Lead Wire

ECG Lead Wire, 1.5mm Molded Safety Din to Dome Snap. Minnesota Wire manufactures both disposable and reusable versions.

Product Specialization for

Medical Cables and Wires

Ultra Flexible

High Flex Life

Tangle-Free

Miniaturization

High Pull-Strength Jackets

Custom Medical Devices

and Equipment

Patient Monitors and Sensors

ECG

EEG

Pulse Oximetry

Pain Management and Drug Delivery Systems

Reusable and Disposable Lead Wires and Medical Cables

Hearing Aid and Audiometric Systems

Automatic External Defibrillator (AED)

Digital Imaging

Electrosurgical Wire and Cable

Neonatal Monitoring

Surgical Lasers

Ultrasound

Learn more about one of our existing products:

Trusted Advisors for Over 50 Years!

Minnesota Wire utilizes a variety of advanced manufacturing methods to produce custom cable assemblies, medical cables, and medical wire.

Patient Monitoring Systems

Patient-to-Monitor Cable Assembly

Custom EMG patient cable for measuring the amount of trauma a patient has incurred to muscles. The signals are so small that any noise in the cable will interfere with the monitoring. Special low-noise materials are used in the cable and terminations to reduce noise.

Minnesota Wire offers a broad range of customizable cable harnesses and medical cable assemblies for patient monitoring systems. We provide complete assistance throughout your entire project—from cable design through product validation. Our custom cable-to-monitor connectors and cable harness systems provide patient comfort, excellent body ergonomics, and safety in high-risk environments. All of our cable assemblies for patient monitoring systems comply with RoHS standards. We provide custom solutions to match your specifications—whether your project is simple or complex.

Custom Patient Cables and Cable Harness Systems

Our design engineers will work with you to develop the perfect medical cable harness systems and cable-to-monitor connectors for your patient monitoring systems. Technology has allowed for many monitoring devices to be taken home for extended patient monitoring. Cable assemblies that are worn by patients for extended periods of time at home have unique requirements. They must be soft, flexible, and rugged. Minnesota Wire can choose the correct materials for effective at-home patient monitoring and patient comfort.

Advancements in the technology of monitoring patients can require unique approaches to connecting to patients. We work with our customers’ engineers to provide concepts, prototypes, and test data to develop the correct custom cable design for each application.

Connector Assemblies

Custom and Overmolded AED Connectors, PCBAs, and Simulator Pads

Even the most advanced manufacturing processes and custom-engineered designs are not enough to create the kind of high-quality products customers have come to expect from Minnesota Wire. To produce custom wire, custom cables, and custom cable assemblies that meet our customers’ high expectations, we use only the highest-quality materials.

Minnesota Wire manufactures a wide array of custom coil cords and coil cord assemblies. The conductor, shielding, insulation, and jacketing material all play a critical role in how the coil cord will perform. From soft (easy to extend) coil cords to rugged (must always retract) coil cords, we know the proper material choices.

PCBAs

Improvements in technology allow for more of the functionality of a device to be incorporated into the cable assemblies. Terminating, sealing, and overmolding PCBAs is challenging and requires unique materials, tool design, and processing. Minnesota Wire has the experience and capability to overmold PCBAs effectively.

We work with a wide range of materials, and will work with you to determine the best material choices for your product’s performance requirements. Numerous material options are available for every component of your custom product.

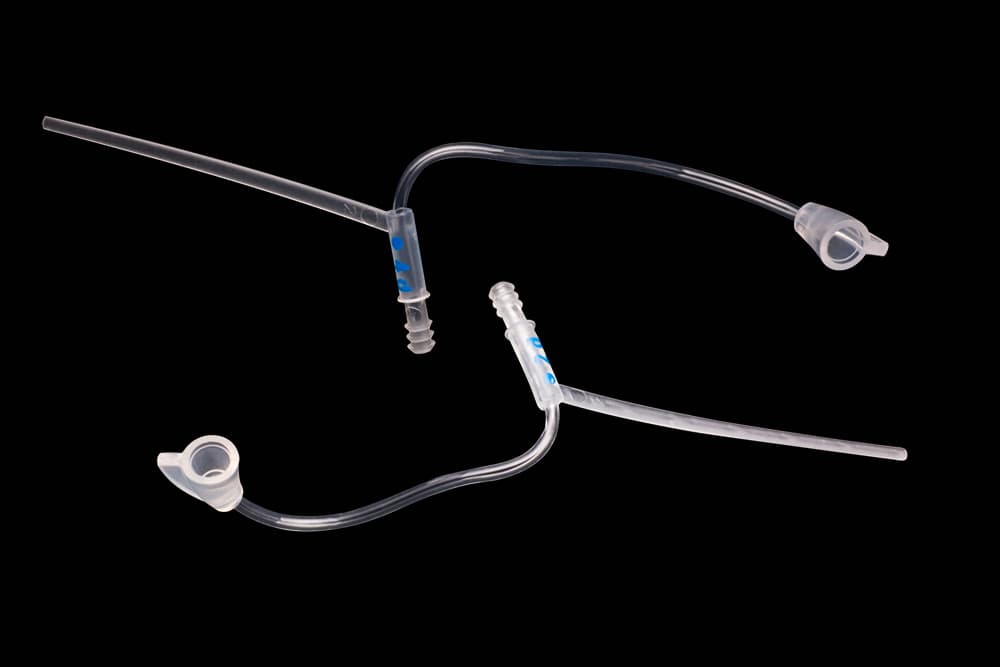

Drug Delivery Systems

Medical Cable Harness Systems and Wire for Drug Delivery and Patient Monitoring

Minnesota Wire offers a complete range of medical wire and medical cable harness system options for drug delivery systems and pain management applications. Our cable assemblies are widely used in medical dispensing systems, electro-stimulation machines, body-worn patient monitoring devices, and a variety of other medical products. Our products are USP/ISO 10993 Compliant.

If your project requires custom medical wires or a custom medical cable harness system for a drug delivery device, we have the knowledge and experience to provide the solution you need. For 50 years, we have specialized in cable and harness assemblies for the medical industry.

Medical Cables and Cable Harness Solutions

We offer solutions for a number of body-worn patient monitoring and drug delivery systems, including ECG (Holter) systems. ECG systems measure and record heart activity.

Medical Cables and Cable Harness Features:

Extended Durability

Fluid-Proof Requirements

High Flexibility with

Exceptional Flex Life

Low Elongation

Low Noise

Medical-Grade Materials

Innovate with Minnesota Wire

Contact Minnesota Wire to learn more about our capabilities or to discuss your project.

Automated External Defibrillator (AED)

Custom-Designed Automated External Defibrillator Connector

Minnesota Wire specializes in producing custom connectors and medical cables for use with Automated External Defibrillators (AEDs). We will custom engineer your medical connectors to match the unique specifications of your device.

Minnesota Wire’s custom connectors are specifically engineered for AEDs. Our connectors can be manufactured with either tinned copper or carbon-fiber conductors.

Minnesota Wire specializes in extruding carbon fiber. We are adept at designing, fabricating, and manufacturing custom connectors for AEDs. Whether you have a complete CAD blueprint for the medical connectors or cable that your project requires or just a basic concept, our engineering team will help you develop custom defibrillator leads that meet your exact requirements.

Custom Designed Defibrillator Leads

Carbon fiber is barely visible on x-ray and other imaging equipment. This eliminates the need to remove the electrode wires from the patient before imaging—providing an invaluable safeguard to the patient without negatively impacting results.

A typical Minnesota Wire AED cable contains 12,000 strands of conductive carbon fiber, yet weighs less than a conventional copper-conductor wire. Our carbon-fiber medical cables are flexible, lightweight, and offer small bend radii together with good low-signal transmission capabilities.

From the simplest designs to the most complex custom connectors, we have the production capabilities to deliver high-performance leads that meet defibrillator manufacturers’ requirements.

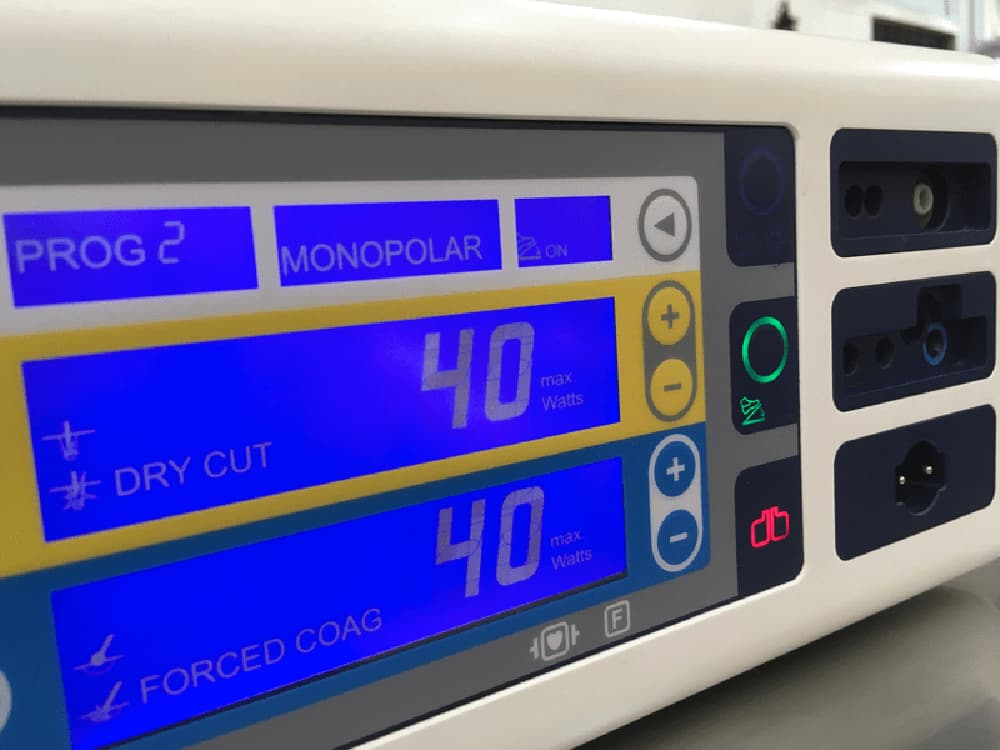

Electrosurgery

Minnesota Wire offers a full line of low-current custom surgical wires and cables designed and manufactured specifically for electrosurgery, including disposable and reusable surgical wires. We specialize in electrical cable and wire assemblies used in control units, laparoscopic tools, electrocoagulation, and other medical applications. Minnesota Wire custom manufactures:

Reusable and disposable surgical wires and cables to meet the specific needs of your application

Surgical cables with coagulating tips for use in both monopolar and bipolar electrosurgeries

Surgical cable assemblies for various coagulating tip configurations

Our electrosurgical lead cables are durable, shockproof, and patient-safe. They can be sterilized via gamma, ETO, or autoclave processes. Reusable models are designed to stand up to repeated sterilization, ensuring a long working life in nearly any application. Fluid-tight overmolding is available for easy cleaning.

Customizable Surgical Cables

All our surgical cables and cable assemblies are manufactured from top quality, FDA-approved medical-grade materials. We offer a variety of material options. We customize surgical cables and assemblies to match your material requirements. Select your conductor materials, insulation, jacketing, connectors, and other features to create electric cables that meet the unique performance requirements of your electrosurgical unit.

Our expert design engineers are available to help you develop the perfect custom solution. Whatever your surgical wire or cable project requires, Minnesota Wire can design and manufacture a custom product to match your requirements.

Electrosurgical Wire and Cable Features

Highly customizable to meet your unique requirements

Customizable material options

Reusable and disposable versions

Available with monopolar or bipolar coagulating surgical tips

Available with corresponding cable assemblies

Sterilize with gamma, ETO, or autoclave

Shockproof

Patient-Safe

Made from FDA-approved medical-grade materials

Hearing Aid Tubes and Wires

Minnesota Wire has extensive experience designing, engineering, and manufacturing hearing aid wire and custom hearing aid tubes. Our expertise in communications engineering includes audiometric systems, assemblies, and communications wire used in a variety of hearing aid technologies.

Minnesota Wire understands the importance of developing a custom solution for your hearing aid tubing, whether it is for use in the ear (ITE), in the canal (ITC), a receiver in the canal (RIC), or body-worn hearing aids. We also produce the small form-factor wiring used in traditional behind-the-ear hearing aids.

Because individuals require hearing aids in different sizes and styles, our custom hearing aid tubes and hearing aid wires are specifically designed for your unique application. We can work from your completed designs, or our design engineers can work with you to develop custom hearing aid tubing and wire that meet the exact requirements of your audiometric systems.

All our hearing aid wires and hearing aid tubes are made from the highest quality materials. Your custom wires and tubes will be manufactured with the conductor materials, shielding, jacketing, connectors, and other materials and components you specify. We make it easy to create a completely custom solution for your particular application.

We have extensive experience working with PEBAX®, a plasticizer-free thermoplastic elastomer that offers remarkable processing ease. The properties of PEBAX make it an excellent choice for extrusion of medical grade tubing. We also supply highly-engineered tinsel and litz wire specialty items, as well as engineered plastics and specialized materials.

Reusable and Disposable Medical Lead Wires

Minnesota Wire is a leading designer and manufacturer of custom reusable and disposable medical cables and lead wires. Our products are ideal for numerous applications, including:

Airway Temperature Monitoring

Body Temperature Monitoring

ECG Devices

EEG Devices

EMG Devices

SpO2 Devices

Minnesota Wire has the automation equipment to cut, strip, and crimp cables for improved quality and reduced costs. The contacts are standard off-the-shelf or custom components. The overmold tooling is designed to replace existing device connectors or can be fabricated for unique custom new devices.

Tangle-Free Medical Wire

Cable Construction

Conductors: 1C

Jacket Material: PU/PVC Blend

Durometer: 65 Shore-A

Color: Black, Red, Yellow, Green, Blue, Violet, Grey, Pink

Tangle-Free Medical Wire Advantages

Cable Properties Promote High Lubricity

High-Stranding Conductor Promotes Flexibility (22 AWG; 154/44)

Jacket Construction Allows for a Smooth Surface

Slides Easily Across Rough Surfaces and Itself

Used in Medical Applications and where the Cable Needs to Slip Easily Across Skin or Material

Medical Grade Body Contact

PVC Jacket Properties

Excellent Resiliency and Flexibility

Abrasion Resistant

Good Elasticity

Toughness and High-Tear Strength (380)

Temperature: -20˚ to 60˚ Centigrade

Custom Medical Cables and Lead Wires

With decades of experience as a medical cable manufacturer, Minnesota Wire knows that an off-the-shelf product is not the right solution for every project. While some manufacturers offer stock products with a few interchangeable features, we deliver custom reusable and disposable medical wires. We manufacture products that are designed and engineered to meet your requirements.

We offer in-house turnkey manufacturing at both our St. Paul, Minnesota and Eau Claire, Wisconsin facilities. This allows us to monitor all production processes for quality and consistency. Our state-of-the-art manufacturing equipment ensures exact repeatability from the first piece to the last. This ensures that every part you order matches your specifications.

Whatever your unique challenge may be, Minnesota Wire can deliver the solution. Our design engineers will work with you to develop lead wires and medical cables that will perfectly fit your application, whether you are starting with a completed design print or a basic concept.

We make custom products with a number

of special characteristics, including:

Any Length

Any Color Wire, Cable, and Fittings

Custom Cables

Custom Softness

Custom Cable and Wire Terminations

Flexibility

Ergonomic Shape and Fit

As needed, we can help you select:

Conductors

Connectors

Filler

Insulation

Shielding

Extrusion Materials

Jacket Materials

Mold Materials

Wire Terminations

Wrap Type

RoHS Compliant, DEHP-Free, and BPA-Free wire lead

options are available on request.

Performance, Reliability, and Longevity

All our reusable and disposable medical lead wires and medical cable products can be shielded to minimize noise and signal interference. Rugged construction makes our lead wires and cables ideal for high-humidity, high-pressure, and high-temperature applications. We use only the highest-quality materials in the production of all our products. We have a broad selection of materials available. Our expert team can help you find the right combination of performance, reliability, and longevity to meet your requirements.

The overmold tooling can be designed to the specific requirements of the project. For disposable cables, the mold tool design includes unique cost-reducing options for loading and unloading speed. Every assembly is designed to the customer’s requirements. Any color is available.

Innovate with Minnesota Wire

Contact Minnesota Wire to learn more about our capabilities or to discuss your project.